Other Poultry Equipment

Vaccinator

Using a vaccinator for a poultry farm can greatly enhance disease management and improve overall flock health. Here’s a guide to what you need to know about vaccinating poultry:

Features:

- Adjustable Heights

- Sufficient Space

- Easy Installation

- Comfort For Birds

- Long Lasting Durability

Types of Vaccinators:

- Manual Vaccinators

-

- Syringe-type: Hand-held devices that are easy to use for small batches.

- Spray guns: For administering vaccines through mist, suitable for larger flocks.

- Automatic Vaccinators

-

- In-line Vaccinators: Integrated into water lines for mass vaccination during drinking.

- Automatic injection machines: Allow for precise doses and quick vaccination.

Key Considrations:

- Vaccine Selection: Choose vaccines based on common diseases in your area

- Timing: Vaccination schedules depend on the type of vaccine and the age of the birds. Follow the manufacturer’s guidelines.

- Dosage: Ensure correct dosage to maximize efficacy and minimize adverse reactions.

- Technique: Proper administration technique is crucial. For example, subcutaneous, intramuscular, or oral routes may be used depending on the vaccine.

Best Practices:

- Training: Ensure that staff is properly trained in the use of vaccinating equipment and techniques.

- Hygiene: Maintain cleanliness to avoid contamination. Disinfect equipment before and after use.

- Record Keeping: Keep detailed records of vaccinations, including dates, vaccine types, and batch numbers for tracking.

Advantages:

- Efficiency: Saves time and labor compared to manual vaccination.

- Accuracy: Ensures consistent dosing and reduces the risk of human error.

- Healthier Flocks: Helps prevent outbreaks of diseases, leading to healthier and more productive birds.

Maintenance:

- Regularly check and maintain your vaccinating equipment to ensure it operates correctly.

- Clean and sanitize equipment to prevent cross-contamination between flocks.

By incorporating a vaccinator into your poultry farm operations, you can improve vaccination efficiency and contribute to the overall health of your flock. If you need specific product recommendations or tips, feel free to ask!

Fogger System

Optimal Environment for Healthy Flocks

Enhance the living conditions of your poultry with our state-of-the-art Fogger System, designed to create a comfortable and hygienic environment. This innovative system delivers fine mist to regulate temperature and humidity, ensuring your birds thrive in optimal conditions.

Key Features:

- Efficient Humidity Control: The fogger system disperses a fine mist, helping to maintain ideal humidity levels in poultry housing, which is crucial for respiratory health and overall well-being.

- Temperature Regulation: By cooling the air in warmer climates, this system helps prevent heat stress, promoting a healthier environment for your flock and improving growth rates.

- Even Coverage: The advanced nozzle design ensures uniform mist distribution, effectively covering large areas to benefit all birds equally.

- Durable Construction: Built from high-quality, weather-resistant materials, our fogger system is designed to withstand the demands of a busy poultry farm, ensuring longevity and reliability.

- Energy Efficient: The system operates with low power consumption, making it an eco-friendly choice that helps reduce operational costs.

- Easy Installation and Maintenance: Designed for quick setup, the fogger system comes with clear instructions and requires minimal maintenance, allowing you to focus on flock management.

- Versatile Applications: Ideal for broilers, layers, and hatcheries, this fogger system can be adapted to various poultry environments, making it a valuable addition to any operation.

Invest in our Fogger System for your poultry farm and create a healthier, more productive environment that supports the well-being of your flock!

De-Beaking Machine

A de-beaking machine for poultry farms is a specialized tool used to trim or remove the beaks of birds, typically chickens, to prevent pecking injuries and reduce aggression within flocks. This process is important for maintaining flock health and minimizing losses due to cannibalism or feather pecking.

Key Features:

- Design:

- Ergonomic Handheld Models: Often designed to be lightweight and easy to handle, allowing for precise control during the de-beaking process.

- Automated Machines: Some models are fully automated and can handle multiple birds quickly, improving efficiency on larger farms.

- Heating Mechanism:

- Many de-beaking machines use heat to cauterize the beak as it is trimmed, which helps to minimize bleeding and reduce pain for the birds.

- Adjustable temperature settings ensure that the heat is appropriate for different age groups and sizes of poultry.

- Cutting Mechanism:

- High-quality blades are designed for clean cuts, which helps reduce trauma and promotes quicker healing.

- Some machines feature safety guards to prevent accidental injuries to the birds.

- Capacity:

- Varies from small handheld devices for individual birds to larger machines capable of processing dozens of birds in a short time.

- Ease of Use:

- User-friendly controls and clear instructions make it easier for farm workers to operate the machine effectively.

Uses:

- Preventing Pecking Injuries: Reduces the risk of feather pecking and cannibalism, particularly in high-density housing situations.

- Managing Aggression: Helps to create a calmer flock environment by minimizing aggressive behavior.

- Maintaining Welfare Standards: De-beaking is often a practice used to comply with welfare standards in poultry production.

Benefits:

- Healthier Flocks: Reduces the incidence of injuries and stress-related issues within the flock.

- Improved Productivity: Healthy, stress-free birds are more likely to perform better in terms of growth and egg production.

- Economic Savings: Preventing injuries and improving flock health can lead to lower veterinary costs and reduced mortality rates.

Considrations:

- Training Required: Proper training is essential to ensure that workers can use the machine effectively and humanely.

- Regulatory Compliance: Farmers should be aware of local regulations regarding de-beaking practices, as some regions have specific guidelines or restrictions.

In summary, a de-beaking machine for poultry farms is an important tool for enhancing flock welfare and productivity. When used properly, it can significantly contribute to the overall health and efficiency of poultry operations.

Flame Gun

A four-way flame gun for poultry farms is an advanced tool designed for efficient pest control, sanitation, and weed management. Its unique design allows for multiple flame directions, enhancing versatility and effectiveness in various agricultural tasks.

Key Features:

- Four-Way Design:

- Multi-Directional Flames: Capable of producing flames in four different directions, allowing for broader coverage and more efficient treatment of large areas.

- Adjustable Flame Settings: Users can customize the intensity and size of the flames to suit specific tasks.

- Material and Construction:

- Durable Build: Typically constructed from heat-resistant materials that withstand high temperatures, ensuring longevity and safety.

- Ergonomic Handle: Designed for comfort and ease of use, minimizing fatigue during extended operations.

- Fuel Source:

- Propane or Butane: Generally powered by propane or butane, offering reliable performance for extended use.

- Safety Features:

- Flame Control Mechanisms: Equipped with safety controls to manage the ignition and extinguishing of flames, reducing the risk of accidents.

- Protective Design: Built with protective shields to help direct heat away from the operator and surrounding areas.

Uses:

- Pest Control: Efficiently eliminates pests like insects and rodents, reducing the need for chemical pesticides.

- Sanitization: Applies heat to surfaces and equipment, effectively killing harmful pathogens and bacteria.

- Weed Management: Controls unwanted vegetation around poultry houses and facilities, enhancing the cleanliness of the farm environment.

Benefits:

- Enhanced Efficiency: The four-way functionality allows for quicker treatment of larger areas compared to single-direction flame guns.

- Environmentally Friendly: Provides an alternative to chemical pest control methods, aligning with sustainable farming practices.

- Cost-Effective: Reduces costs related to chemicals and labor by providing a direct method for pest and weed management.

Considrations:

- Training Required: Proper training is essential to ensure safe and effective use, particularly given the multi-directional flames.

- Local Regulations: Users should be aware of any regulations regarding the use of flame-based tools in agricultural settings.

In summary, a four-way flame gun for poultry farms is a versatile and efficient tool that aids in pest control, sanitization, and vegetation management. Its design enhances operational efficiency, making it a valuable asset for poultry farmers looking to improve their management practices.

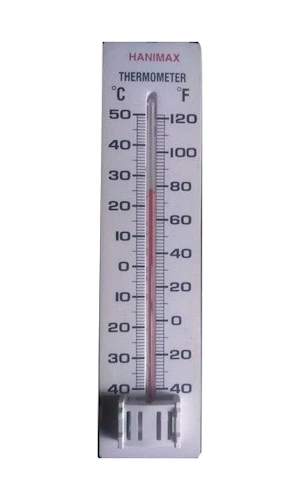

Temprature Meter

A temperature meter for poultry farms is an essential tool used to monitor and manage the environmental conditions within poultry housing. Maintaining optimal temperature levels is crucial for the health and productivity of poultry, as extreme temperatures can lead to stress, reduced growth, and increased mortality.

Key Features:

- Types:

- Digital Thermometers: Provide quick and accurate readings, often with features such as backlit displays for easy visibility.

- Infrared Thermometers: Allow for non-contact measurement, which is useful for checking the temperature of birds or specific areas without disturbing them.

- Data Loggers: Record temperature over time, allowing farmers to track trends and make informed management decisions.

- Temperature Range:

- Designed to measure a wide range of temperatures suitable for poultry environments, typically from 0°C to 50°C (32°F to 122°F), depending on the specific needs of the farm.

- Accuracy:

- High accuracy is crucial for reliable readings; many temperature meters come with calibration options to ensure precision.

- Portability:

- Many models are lightweight and battery-operated, making them easy to carry around the farm for quick checks.

- Humidity Measurement (Optional):

- Some advanced models also measure humidity, providing a comprehensive view of the environmental conditions affecting poultry.

Uses:

- Monitoring Housing Conditions: Regularly checking the temperature in poultry houses helps ensure that the environment remains within optimal ranges for growth and health.

- Incubation Monitoring: In hatcheries, temperature meters are critical for monitoring incubators to ensure proper conditions for egg hatching.

- Stress Management: Helps identify temperature extremes that may lead to heat stress or cold stress in birds.

Benefits:

- Improved Bird Health: By maintaining optimal temperatures, farmers can reduce stress and improve overall flock health and productivity.

- Informed Management Decisions: Continuous monitoring enables farmers to make timely adjustments to heating or cooling systems as needed.

- Cost Efficiency: Reducing temperature-related issues can lead to lower mortality rates and improved growth, enhancing the overall profitability of the farm.

Considrations:

- Calibration: Regular calibration is necessary to maintain accuracy.

- Placement: Proper placement of the temperature meter is essential to get representative readings of the environment, avoiding spots with direct drafts or sunlight.

In summary, a temperature meter for poultry farms is a vital tool for ensuring the well-being of poultry by monitoring environmental conditions. It aids in effective management practices, contributing to better health, productivity, and profitability in poultry operations.